The Best Products

Introduction to the Components of Air Conditioning Cabinets

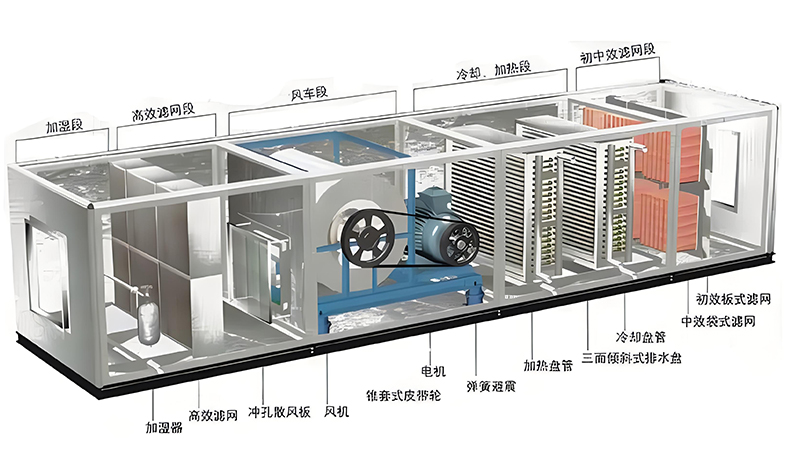

1、 Air inlet section

The air inlet section of an air conditioning cabinet refers to the part where air enters the cabinet from the outside, usually including an air inlet and an air duct. The position of the air inlet is usually on the roof or outside the wall to avoid pollution and noise interference. The air inlet duct is a pipe that connects the air inlet and the fan cabinet, usually made of fire-resistant materials.

2、 Filter section

The filtration section refers to the part between the intake section and the refrigeration/heating section, which is an important part for filtering the air entering the fan cabinet. The filtering section is usually composed of a filter screen and a filter frame, which is used to reduce the content of dust, particulate matter, pollen, etc. in the air and ensure the cleanliness of indoor air.

3、 Refrigeration/heating section

The refrigeration/heating section refers to the part that cools or heats the air entering the cabinet. Air conditioning cabinets typically use equipment such as refrigerants or heaters to cool or heat the air through a hair dryer, in order to meet indoor temperature requirements.

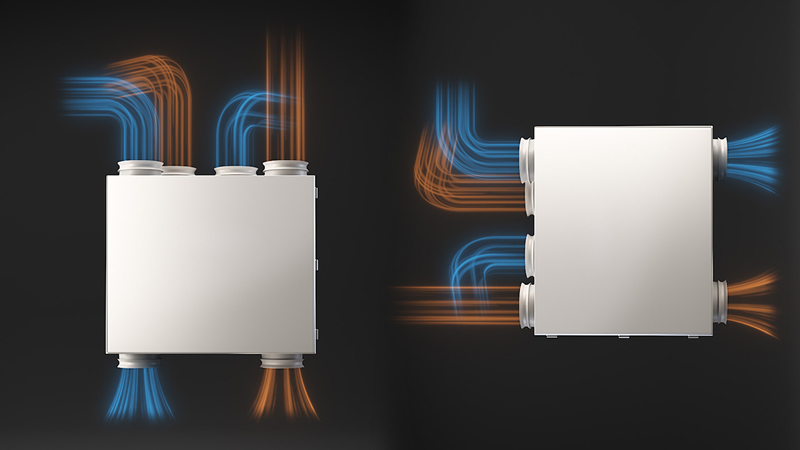

4、 Mixed air section

The mixing section refers to the part where the air passing through the cooling/heating section is mixed. Generally speaking, indoor air needs to be mixed with fresh air to achieve comfortable temperature and humidity. The mixing section usually consists of a cooler/heater and a mixing chamber.

5、 Exhaust section

The exhaust section refers to the part where the air passing through the mixed air section is discharged from the room. The exhaust section is usually composed of an exhaust outlet and an exhaust duct. The exhaust outlet is usually located on the wall or rooftop, and the exhaust duct is connected to the exhaust outlet and fan to discharge waste gas from the room.

In short, an air conditioning fan cabinet is a system composed of multiple parts, each playing a different role. Maintaining the operation of each part is essential to achieve the best cooling/heating effect and cleanliness.